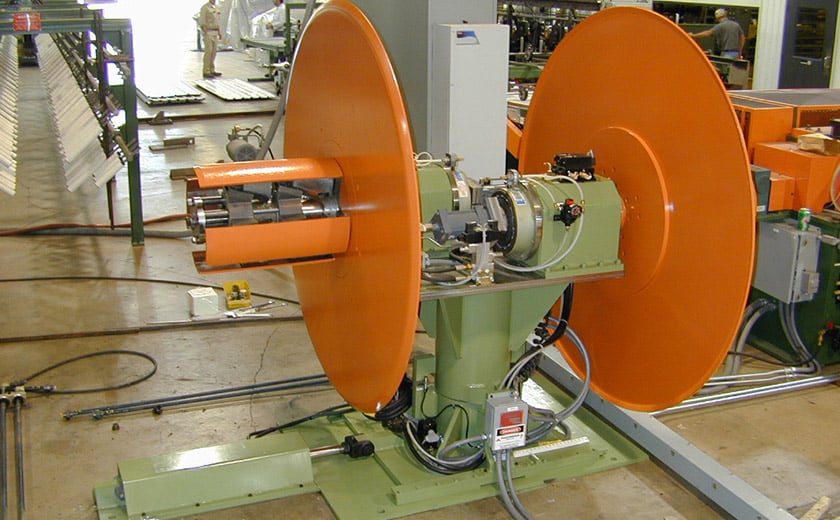

Optimize Run Time

If you are looking to optimize the most of your production run time, inquire about our double mandrel models. Double mandrel models allow you to "stage" a coil for faster thread up times, thus resulting in less down time and more product being produced.

We have four double mandrel options, all of which can be utilized as a retro-fit on your existing roll forming line, or added to a new Bradbury line customized to your manufacturing needs.

SRDE-6.5 / 6,500 lbs.

SRDE-6.5 has a mandrel capacity of 6,500 lbs making it a great option for narrow coils. This uncoiler is capable of running at various speeds up to but not limited to 500 ft. per min. As with all of the double mandrel uncoilers, production will increase and changeover time will decrease! The double mandrel uncoilers are the best option to keep your line producing product with very little downtime.

Common features include:

- Powered Mandrel Expansion

- Powered traverse shift to line up coil with machine in feeder

- Manual Slewing / Rotation of the Uncoiler

- Optional: Powered pay-off with Loop arm speed control

- Tight loop prevention - Has the ability to shut the line down in the event of tight loop

- Feeding your roll former at speeds of 500 feet per min.

SRDE-10 / 10,000 lbs.

Our SRDE-10 Double Mandrel Uncoiler offers 10,000 lbs capacity per mandrel. If you are wanting to increase the efficiency of your line new or existing line, this is a great way to do so. Having a coil "staged" and ready for a change dramatically reduces the time needed during changeovers.

Common features include:

- Powered Mandrel Expansion

- Powered Slewing / Rotation of the Uncoiler

- Powered pay-off with Loop arm speed control

- Optional: Overarm to assist in threading up and retreading heavier gauge material

- Tight loop prevention - Has the ability to shut the line down in the event of tight loop

- Feeding your roll former at speeds of 300 feet per minute.

SRDE-20 / 20,000 lbs.

Our SRDE-20 Double Mandrel Uncoiler offers a 20,000 lbs per mandrel capacity, this is one of or most popular options for new machine configurations.

Common features include:

- Powered Mandrel Expansion

- Powered traverse shift to line up coil with machine in feeder

- Powered Slewing / Rotation of the Uncoiler

- Optional: Powered pay-off with Loop arm speed control

- Optional: Overarm to aid in thread-up and wrapping of material

- Tight loop prevention - Has the ability to shut the line down in the event of tight loop

- Feeding your roll former at speeds of 300 feet per minute.

SRDE-50 / 50,000 lbs.

Our SRDE-50 Double Mandrel Uncoiler has a weight capacity of 50,000 lbs. per mandrel!

Common features include:

- Powered Mandrel Expansion

- Powered traverse shift to line up coil with machine in feeder

- Manual Slewing / Rotation of the Uncoiler

- Optional: Powered pay-off with Loop arm speed control

- Optional: Overarm to assist in thread up and wrapping of heavy gauge coils

- Tight loop prevention - Has the ability to shut the line down in the event of tight loop