Bradbury Trim Shop equipment is manufactured in a 40,500 square foot plant adjacent to our main facility. This plant is dedicated to producing a full line of trim shop machines and cutting manufacturing lead time on all orders. We offer trim roll formers, folders, gutter roll forming lines, slit/CTL recoil lines, Slit/CTL lines, portable hemmers, coil tippers, coil cars, and stand-alone sheet slitters. Call us today!

Trim Rollformers

Bradbury has supplied Multi-Profile Trim Rollformers to the metal building industry for more than 60 years. Whether you require residential or commercial ridge caps, low or high rib corners, sculptured rakes, or J or jamb trim, Bradbury multi-profile trim roll formers give you profile flexibility while they save floorspace.

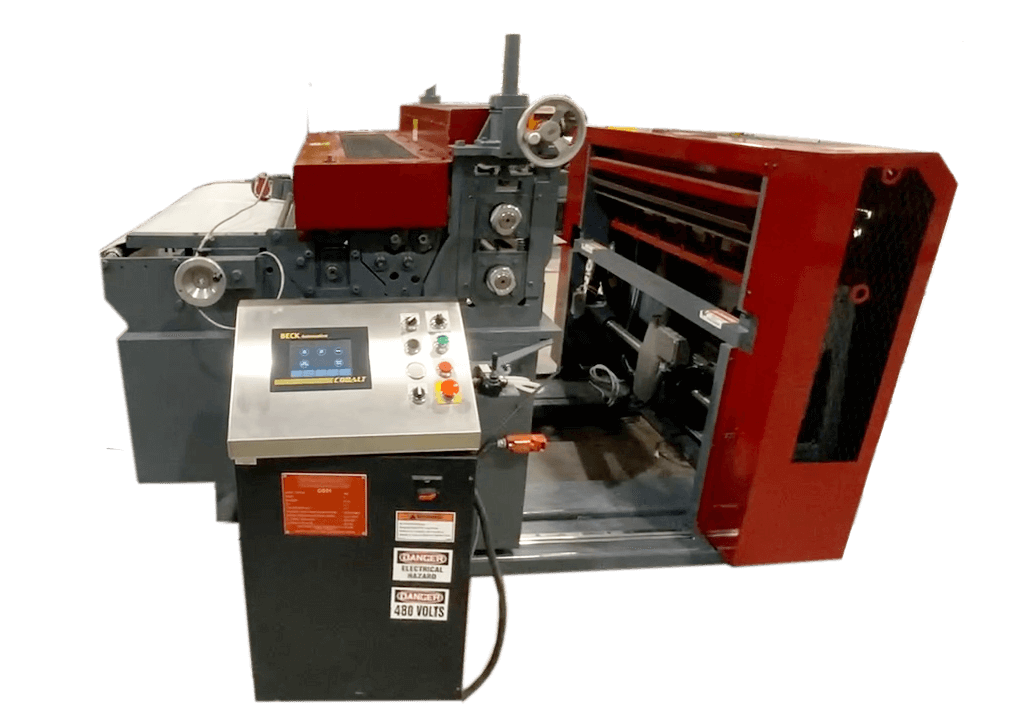

Panther Cub III™ Slit CTL

The Bradbury Panther Cub III™ light gauge slit, cut to length unit is ideal for trim shop work and lighter rollforming applications. It allows you to slit and shear or slit and recoil. Features include a moving front end allowing operators easy access to slitter knives, a handwheel adjust lead-in, precision depth control, the ability to stop and move slitter knives to reduce scrap, an upcut shear for sheet-on-sheet stacking, and the Beck Automation Cobalt control.

Hydraulic Long Folders

Bradbury Folders give you the metal forming capabilities of a roll former or large press brake at a fraction of the cost. You also benefit from extraordinary versatility in creating high-margin trim shop building components.

XBEND DOUBLE FOLDER

Bradbury has a partnership with Biegemaster to distribute the Xbend Double Folder and offer support in the USA.

Working Length of 21 ft. / 6400mm.

Back Guage Depth 0.787-49.2".

Bending Beam Speed 4 seconds.

Rotation Range of 150 degrees.

Gutter and Downspout

Gutter roll forming machine and downspout roll forming machine options include half round gutter, quad gutter, square line gutter, sculptured gutter, square downspout, and more!

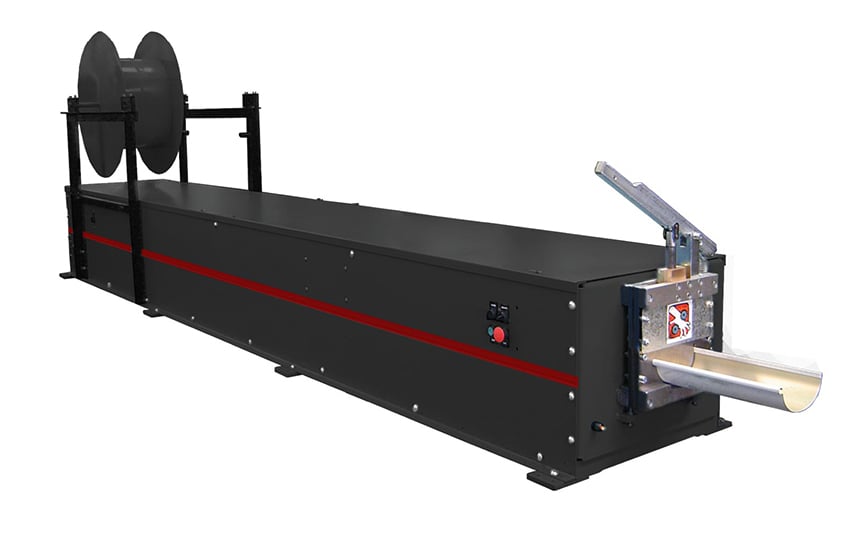

Tension Stand and Recoiler

Pneumatic air bladder type tension pad

Manual cross cut shear mounted to exit end of tension stand that eliminates the need to "rethread" when producing pup coils.

Hydraulic pusher arm assembly to assist in removal of slitted coils

Loop arm for speed control - Frequency inverter drive

Jog pendant controller with forward and reverse control

Cantilevered mandrel with powered expansion

Recoiler expansion range - 19" (484mm) - 20" (508mm)

Designed to use 1/2" cardboard cores with 20" (508mm) ID

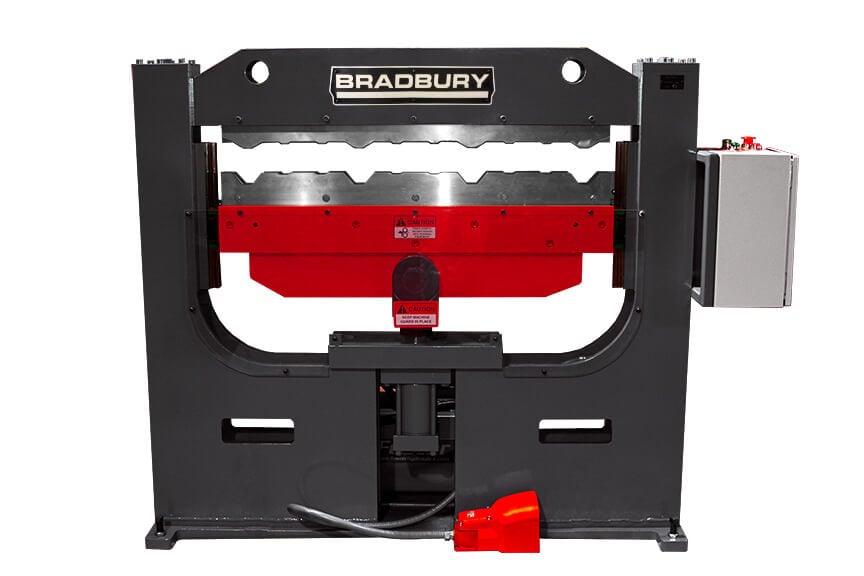

Ridge Cap Bender

Hydraulic powered press

Produced high quality formed ridge caps

Pitches up to 4 on 12

Multiple profile dies

Formed dies utilize D2 tool steel

Transition Notch Press

Stand alone notch and cutoff press to produce gambrel and transition trim blanks by taking a profile slug cut. Blank is formed offline on a hydraulic trim folder or press brake to produce custom trim.

Pre-Painted, Galvalume, Galvanized Steel

.020" Maximum, .015" Minimum, 26 to 29 Gauge

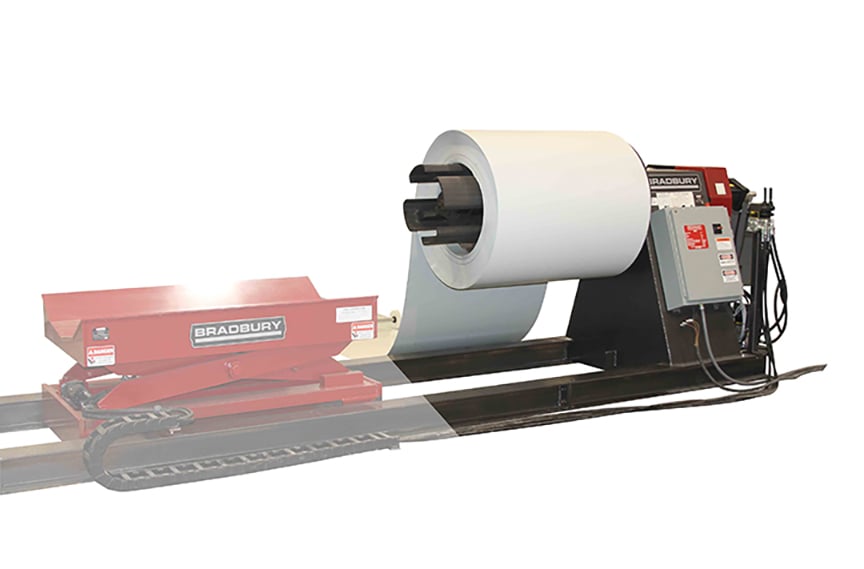

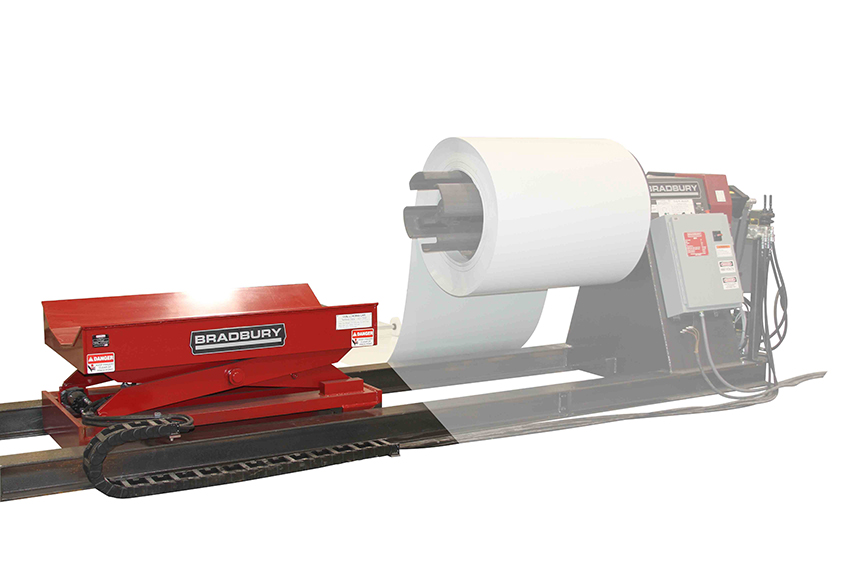

TS12 Uncoiler

Single mandrel, 12,000 lb. (5.4 Metric ton) capacity

48 1/2" (1230mm) Maximum material width

Hydraulic drive payoff with loop control up to 200 FPM

Hydraulic mandrel expansion

Self-contained hydraulic power unit

Expansion range 18" (457mm) - 21" (533mm)

TS12 Coil Car

Cradle type

12,000 lbs. (5.4 Metric Ton) capacity

Maximum coil dimensions: 48" (1220mm) X 45" (1143mm) OD

Hydraulic power from recoiler unit

Complete with track and hydraulic drive

Coil Keepers are available

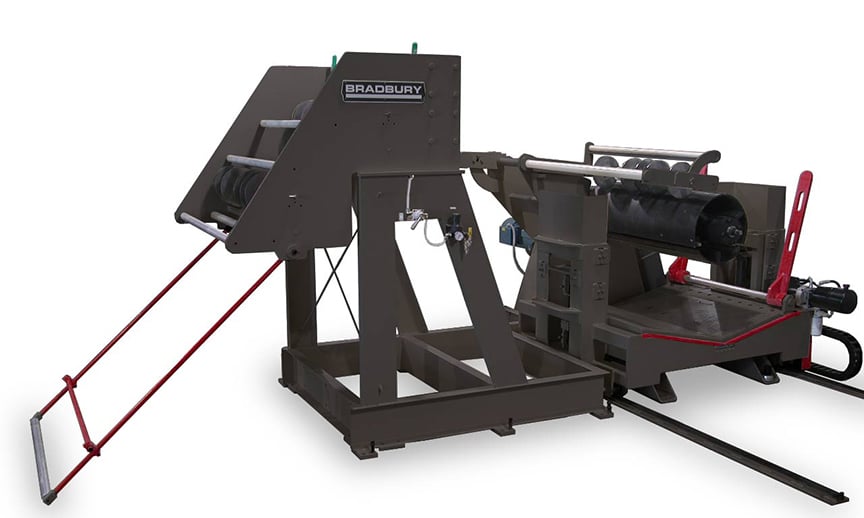

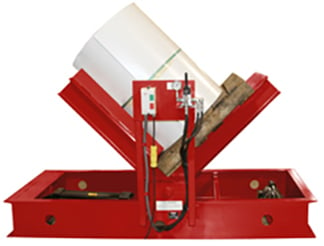

Coil Tipper

12,000 lb. Capacity

Maximum Coil Dimensions 48" wide X 48" OD

Self Contained Hydraulic Power Supply

Approximate Cycle Time is 1 Minute

230 Volt, 60 HZ, 1 PH

Stand Alone Slitter

42" Passline

Maximum Sheet Width 48.50" / Minimum 4.0"