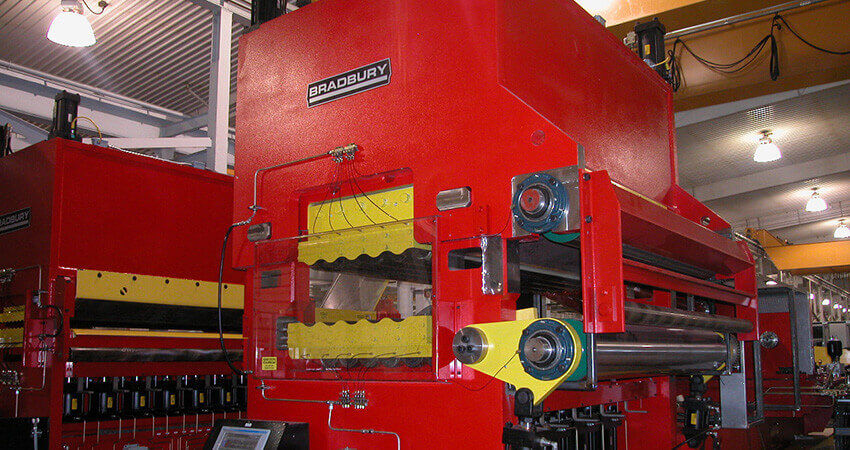

REDUCE SCRAP AND OUT OF FLAT MATERIAL with a Bradbury Leveler

Bradbury introduced hydraulic leveling in the mid 1980s. Since then, Bradbury Hydraulic Roller Levelers have become the most versatile and efficient metal flattening machines available. We minimize adjustments by moving only the lower portion of the leveler. With brute hydraulic force, we can neutralize stress while delivering a premium quality product day after day. Development of world-class controls and a unique set of options have made our levelers the easiest to operate and most productive – while maintaining outstanding stretching and flattening repeatability.

e-Drive® & e-Drive 3 Leveling Systems

Bradbury's patented e-Drive® leveling systems equalize internal material stresses while delivering superior flat products for our customers around the world.

Auto-Selective™ Levelers

Bradbury's Auto-Selective™ levelers ensure repeatability and increase productivity.

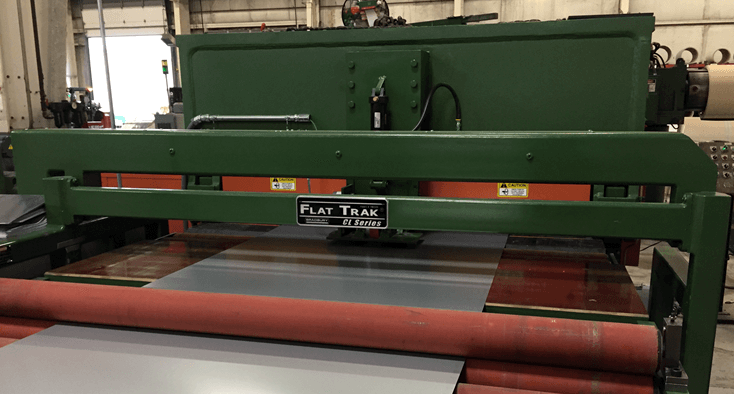

Flat Trak® CL

Bradbury's Flat Trak® CL monitoring system measures, displays and makes automated adjustments to the e-drive® leveler.

Lift Top Levelers

Roll inspection, maintenance, and cleaning are fast and easy with Bradbury's lift top leveler.

Stretch Levelers

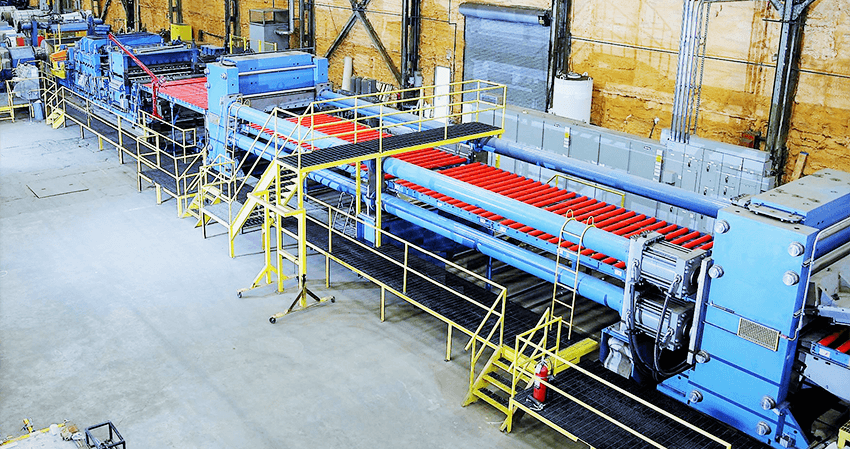

ATHADER-LEVELTEK stretch leveler cut-to-length lines incorporate the latest developments to improve efficiency in processes and production.

Cartridge Levelers

The cartridge leveler offers the flexibility to run a wide range of material thickness.

Architectural Roller Levelers

The Architectural™ Roller Leveler is designed specifically for precise flattening of continuous or precut pieces of metal in typical press room applications.

Roll Stack Removal

If your leveling application requires frequent roll cleaning, Bradbury offers a time saving solution with the Roll Stack Removal System.

Bradbury FLAT BOOK™

By C.B. "Brownie" Cox, Bradbury Leveler Product Manager

Learn the basics of roller leveling and the three stages of the leveling process in Bradbury's The Flat Book™

EXPERIENCE THE BRADBURY GROUP ADVANTAGE