taking your projects from design to fabrication.

Comprehensive custom roll forming services for light and heavy gauge applications.

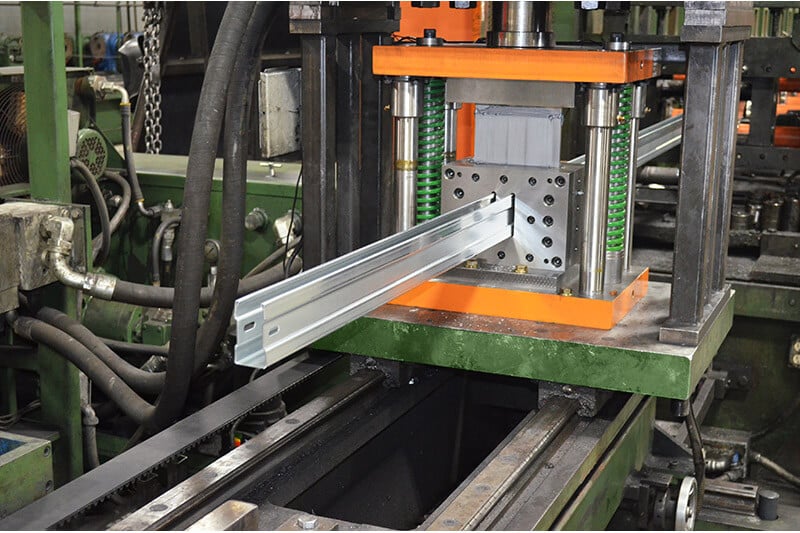

All The Right Equipment

The 51,000 square-foot manufacturing space in our main plant houses ten rollforming lines with ample room for specialty equipment.

All of our machinery is unrivaled for reliability and the rugged construction that sustains consistent quality and dimensional integrity.

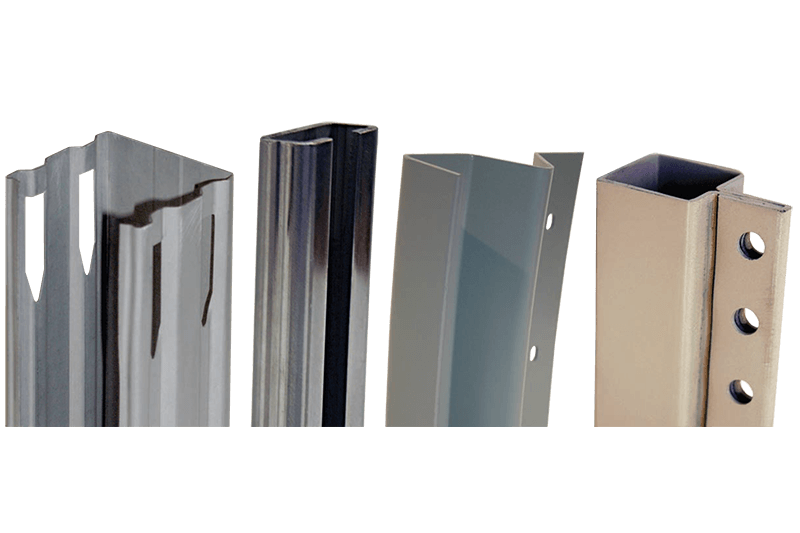

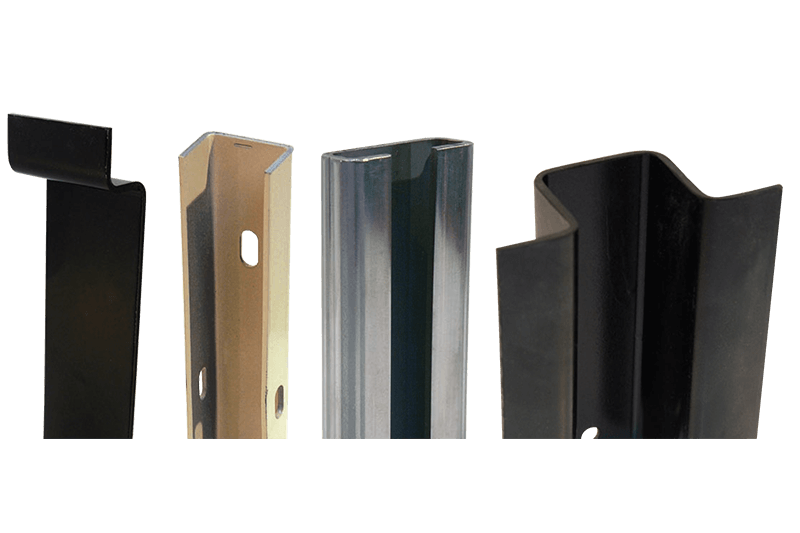

Custom Rollforming Capabilities

- Material Thickness from 30 ga to 1/2" thick

- Steel: CRS, HRS, HSLA, Aluminum, Copper

- Stainless Steel: 200, 300, 400, Series SS, Polished, Hardened

- Pre-Coated Steel: Pre-Painted, Galvanized, Galvanneal, Galvalume

- Strip Widths up to 24" wide

- Inline Punching & Notching

- Inline Welding

- Inline Curving and Bending

- Rollformed Rings and Ring Segments

- Ten Rollforming Lines

- Maintenance Free Tooling

- Standard Shapes from Existing Tooling

- Simple to Complex Shapes

- Engineering and Design Assistance

- Secondary Processes Available

Secondary Process Capabilities

- Power Coat and Paint

- Assembly

- Welding

- Offline Punching & Notching

- Robotic Welding

- Hot Dip Galvanizing

- Inventory Parts for J.I.T. Shipping or Release

- Laser & Plasma Cut

Need us to roll form your profiles?

Custom Rollforming Corp.'s facility is equipped to handle a wide variety of roll forming operations efficiently and economically. We can produce simple or complex roll form shapes. Let us manage the product flow to your facility and save the space and expense of warehousing a large inventory of parts. We review your production requirements and usage cycles to target the output, stocking, and delivery timing to accommodate your production schedule. We track parts and send your purchasing department detailed reports.

industries We serve

- Transportation

- Material Handling

- Office Furniture

- Electrical

- Construction

- Off-Road Equipment

- Recreational Vehicles

- Consumer Products

- Solar Energy

- Point of Purchase

- Agriculture

- Filtration

- Lighting

Agriculture

CRC has supplied various components for grain storage and drying, harvesters, and swathing equipment. CRC's ability to roll form heavy gauge steel with yield strengths reaching 100,000 PSI gives our customers high wear components with the tolerances they need.

We currently form:

- Heavy Gauge Punched Angles

- J Channel Profiles

- Cutter Bar Supports

- Feeder House Slats

- Grain Dryer Ring Components

- Grain Bin Wall Supports

construction

Rollforming is the fastest, most cost-effective manufacturing method to produce your structural components for the Construction Industry.

We currently form:

- Material Handling Components

- Overhead Crane Track

- Commercial Green House Components

- Steel Framing Components

- Sub Assembly Services Available

- Stocking Programs Available

solar

The Bradbury Group has been serving North America's solar energy market since 2011. We have over 50 years of experience roll forming structural steel components for a variety of different markets.

We currently form:

- Ground Mount Structures

- Roof Mount Structures

transportation

CRC has many years of experience roll forming components for the transportation industry.

We currently form:

- Dump Bed Stiffeners

- Seat Tracks

- Trailer Corner Transition profiles

- Conductor Rail for Commuter Trains

- Welded Tube Profile for Buses

- Bus Rub Rails