New In-Stock Equipment

Bradbury Group has equipment that is typically in stock and available for shorter delivery times.

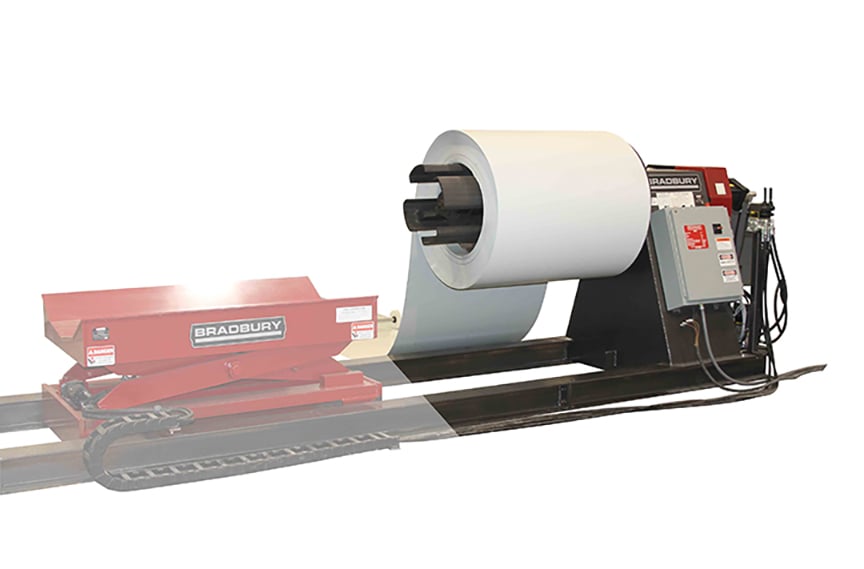

TS12 Uncoiler

Single mandrel, 12,000 lb. (5.4 Metric ton) capacity

48 1/2" (1230mm) Maximum material width

Hydraulic drive payoff with loop control up to 200 FPM

Hydraulic mandrel expansion

Self-contained hydraulic power unit

Expansion range 18" (457mm) - 21" (533mm)

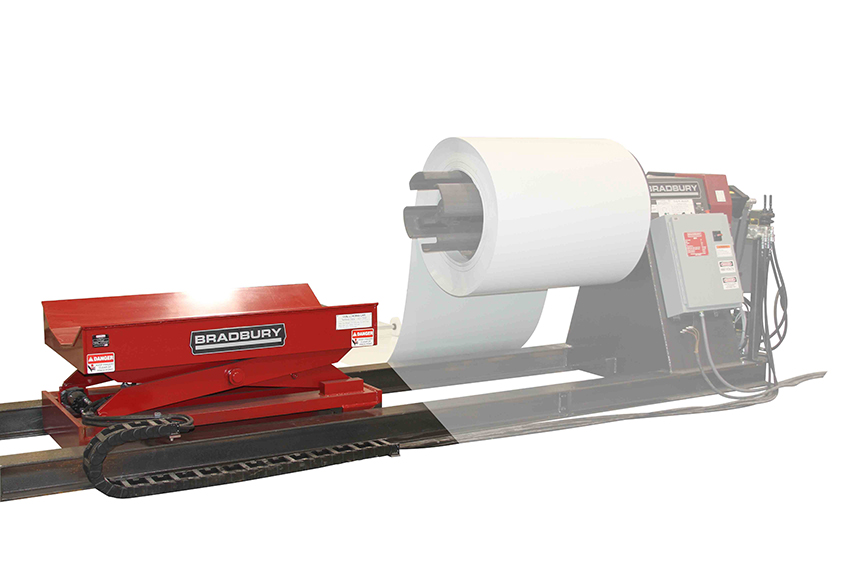

TS12 Coil Car

Cradle type

12,000 lbs. (5.4 Metric Ton) capacity

Maximum coil dimensions: 48" (1220mm) X 45" (1143mm) OD

Hydraulic power from recoiler unit

Complete with track and hydraulic drive

Coil Keepers are available

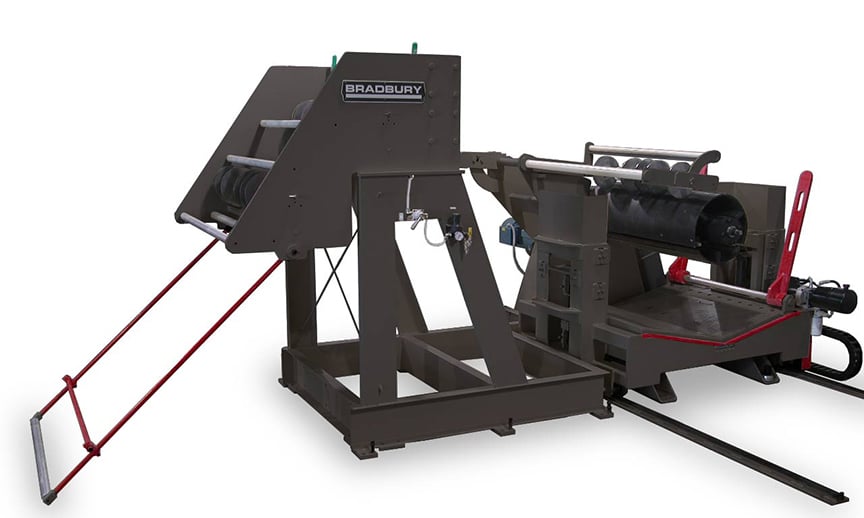

Slit Cut-to-Length Panther Cub III

Drive Side Justified for Simple Setups

Frequency Inverter Drive on Drive Rolls with Separate Motor for Shear Head Actuation

4" (101mm) Diameter Slitter Arbor with 5 - 1 1/4" D2 Hardened Knife Pairs Supplied (Set Screws Lock on Knives)

Beck Automation Cobalt Multi Batch Controller

150 FPM variable speed

Optional Film Applicator

Tension Stand and Recoiler

Pneumatic air bladder type tension pad

Manual cross cut shear mounted to exit end of tension stand that eliminates the need to "rethread" when producing pup coils.

Hydraulic pusher arm assembly to assist in removal of slitted coils

Loop arm for speed control - Frequency inverter drive

Jog pendant controller with forward and reverse control

Cantilevered mandrel with powered expansion

Recoiler expansion range - 19" (484mm) - 20" (508mm)

Designed to use 1/2" cardboard cores with 20" (508mm) ID

21' X 18 Gauge CNC Trim Folder

18 Gauge (Grade D), 22 Gauge Stainless Steel

Working length 6.5 meters

Rotation range up to 145 degrees

Cycle time for 90 degree bend approx. 4 seconds

Five (5) Bradbury Hybrid FeatherFinger™ Assemblies Included

Each Finger Assembly can be positioned anywhere along the backgauge extrusion

Backgauge depth of 38 inches

Beck Intelli-Fold™ with Touchscreen and Graphic Display

Other models available with special order

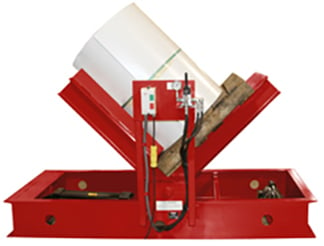

Coil Tipper

12,000 lb. Capacity

Maximum Coil Dimensions 48" wide X 48" OD

Self Contained Hydraulic Power Supply

Approximate Cycle Time is 1 Minute

230 Volt, 60 HZ, 1 PH

Transition Notch Press

Press and die designed to accept a 44" maximum wide blank

Press and die designed to produce a lead/trail Ag panel pattern

One cycle of the press will produce two (2) profiled blanks ready to be finish formed on the trim folder to produce transition or Gambrel Trim

Hydraulic power unit inclued

Other profile dies available