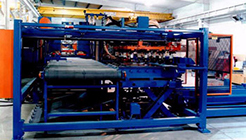

Bradbury Automated Production Systems offer ease of operation and shorter production time by allowing you to convert coil or sheet metal into finished products in ONE continuous operation.

Custom Engineered Equipment

The Bradbury Co., Inc. specializes in designing and building customized manufacturing equipment for your unique product production requirements and structure configurations. Bradbury's Automated Production Systems offer ease of operation and shorter production time by allowing you to convert coil or sheet metal into finished products in ONE continuous operation

Subcomponents are automatically positioned and fastened, often eliminating many secondary operations. Automation minimizes the time required to change lengths, widths, punches, and notches. Bradbury meets the demands of JIT production by providing sophisticated communication software.

Bradbury Automated Production Lines include appliance components, shelving & racking, hot water heater components, steel furniture, and vending machine cabinets.

Uncoil/Decoil

Destack

Level

Punch

Notch

Draw

Rollforming