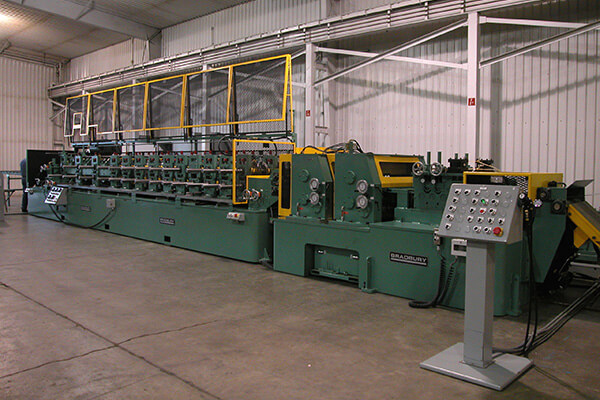

Efficient & Innovative Production

Bradbury's Viper® Rotary Punch options use proprietary Vertical Approach™ technology and high-speed rotary mechanics. They feature standard linear punch tooling which makes maintenance easy and economical.

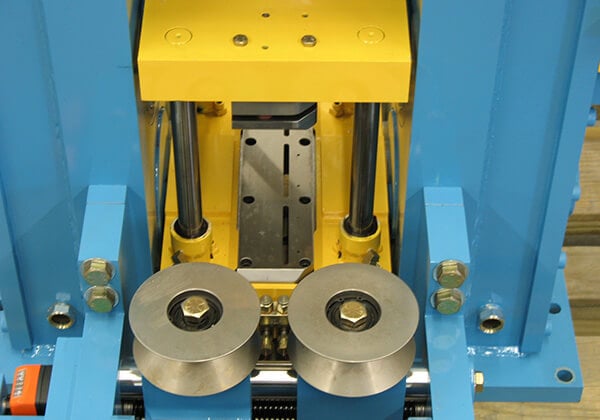

DW Viper®

- 5 ton capacity

- Simple Vertical Approach™ open/close operation

- Production capabilities that exceed drum-type rotary systems without the specialized maintenance requirements for sharpening concave punches.

- Designed to use conventional punch tooling. Does not require concave punch or die tooling.

- Tooling life exceeds that of concave tools.

- Eliminates the need for special equipment for maintaining punch tooling.

- Servo controlled acceleration capable of 500 FPM with hole centers at a minimum of 12".

- Mounted on roll former base to ensure alignment with centerline of tooling roll space and decrease the time required at install.

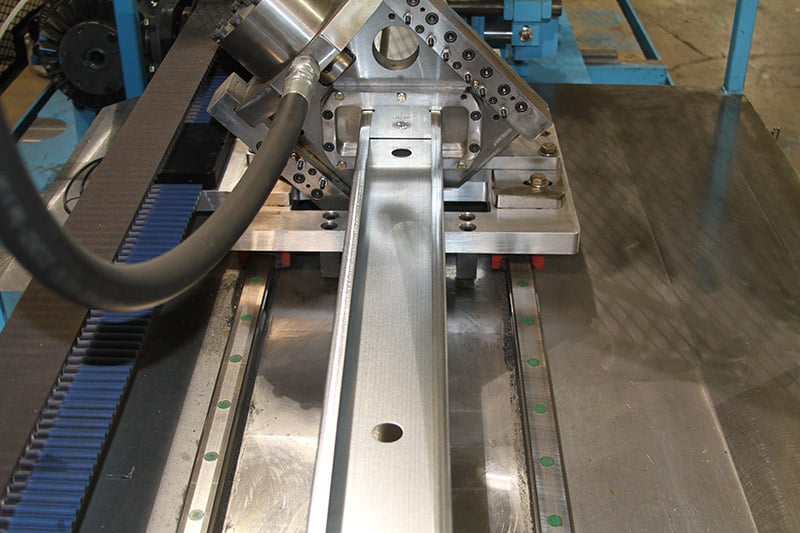

Light Structural VIPER®

- 15 ton capacity

- Simple Vertical Approach™ open/close operation

- Production capabilities that exceed drum-type rotary systems without the specialized maintenance requirements for sharpening concave punches.

- Designed to use conventional punch tooling. Does not require concave punch or die tooling.

- Tooling life exceeds that of concave tools.

- Eliminates the need for special equipment for maintaining punch tooling.

- Servo controlled acceleration capable of 500 FPM with hole centers at a minimum of 12".

- Mounted on rollformer base to ensure alignment with centerline of tooling rollspace and decrease the time required at install.

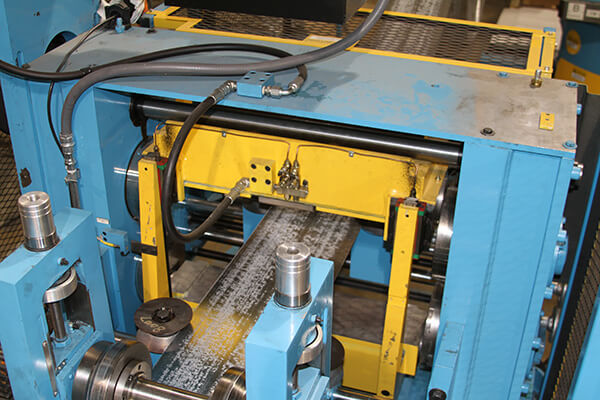

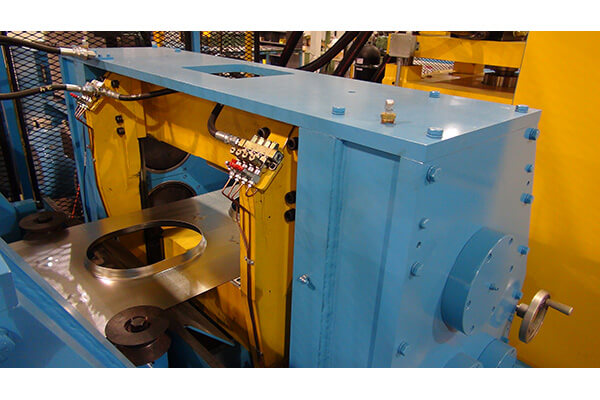

Structural VIPER®

- 30 ton capacity

- Simple Vertical Approach™ open/close operation

- Production capabilities that exceed hydraulic systems without the specialized maintenance requirements for sharpening concave punches

- Designed to use conventional punch tooling and shear blades

- Eliminates the maintenances issues surrounding the acceleration of a presses designed for 0.135” material thickness

- Four sided shear blades

- Servo controlled acceleration – capable of 300 FPM with hole centers at a minimum of 24”

- Includes roller straightener to remove coil set from material

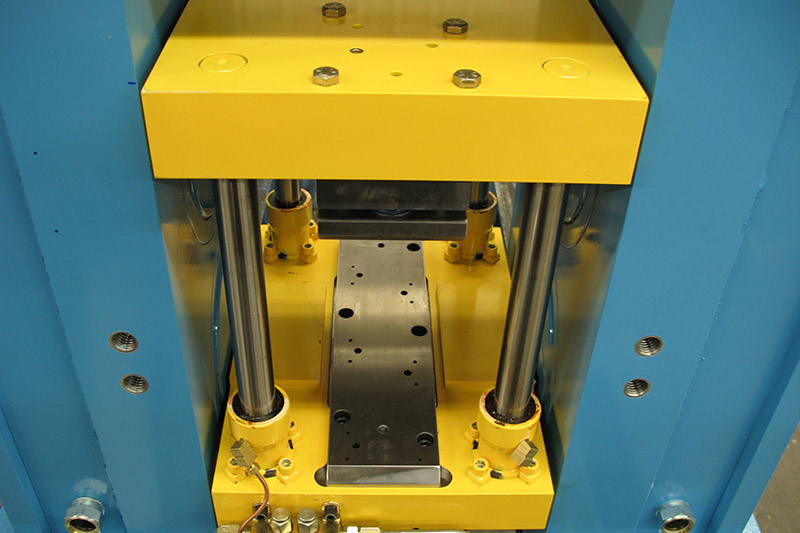

ACCESSORY VIPER®

- Simple Vertical Approach™ open/close operation

- Four Post Style

- Designed to use conventional punch tooling

- Servo controlled acceleration

- Includes servo motor, gearbox, and amplifier