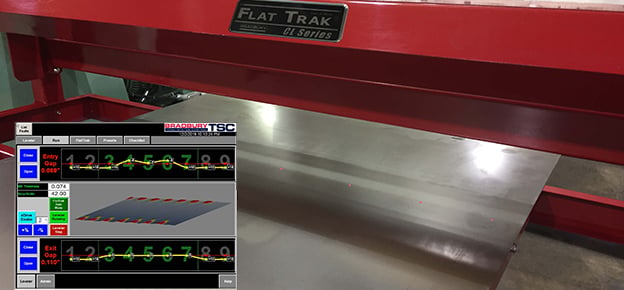

Accurate

The new FlatTrak CL incorporates a laser measurement system to acquire an accurate shape profile. This process happens in real time and is displayed on the operator screen in the form of a three dimensional topographical view. It is also measured in I-Units so that verification of flatness is achieved per ASTM A568.