Our Vision:

To be the most trusted and preferred supplier in the global markets we serve.

The Bradbury Group of companies design and manufacture high-quality, productivity-enhancing metal processing equipment for customers around the world including innovative roll forming production lines for numerous industries, insulated metal panel lines, coil processing lines, levelers, slitting lines, metal tile roofing production lines, controls, and more. We also offer individual components such as uncoilers, coil cars, folders, embossers, calendering machines, and more.

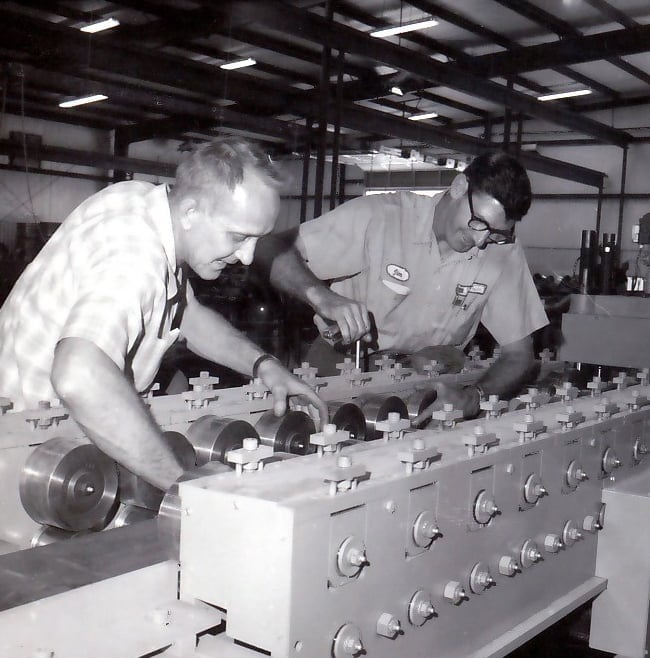

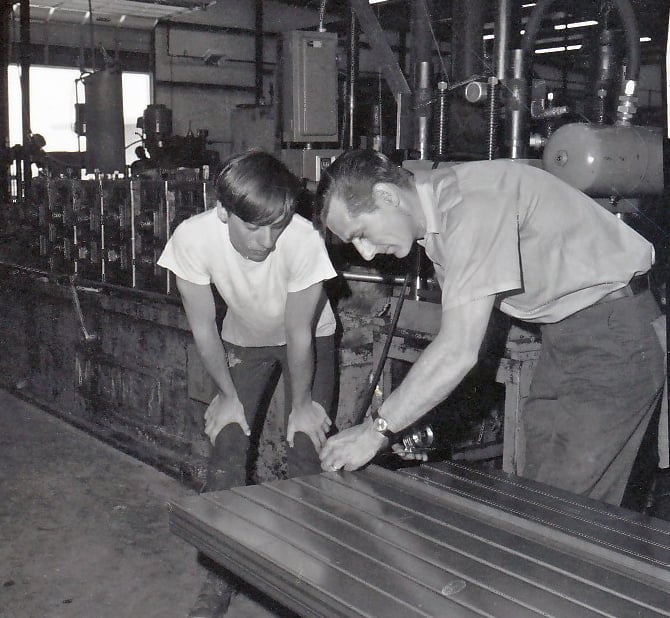

we have over 60 years of experience!

Our combined know-how enhances the capabilities of each company and enables us to apply a wealth of experience to the design, construction, and ongoing support of the tools that will help your business grow. Whether you need a single roll former or an entire manufacturing system, we have the expertise and the dedication to build equipment that will exceed your expectations.

bRADBURY gROUP vALUES & bELIEFS

wE CENTER OUR BUSINESS PRACTICES AND HABITS AROUND THE FOLLOWING:

INTEGRITY, PERSONAL IMPROVEMENT, COMMUNITY, EXPECTATIONS,TRUST, RELATIONSHIPS, SAFETY, AND COMMUNICATION.

.png)

THE BRADBURY CO., INC.

Based in the heartland of Kansas, and headquarters for The Bradbury Group of companies, Bradbury has been in business for over 60 years. Family owned and operated, we are a recognized manufacturer of roll forming, coil processing, leveling, and automated production systems for a wide range of industries. You can be confident that Bradbury equipment incorporates the latest technology and is unsurpassed in quality and durability.

Alliance machine and engraving, llc

Alliance machine and engraving, llc

Alliance Machine and Engraving, LLC., located in Ashland, VA, was started in 2011. Alliance’s manufacturing capabilities span a broad range of products and industries including: Embossing Machines & Rolls, Calendering Equipment and Composite Lumber Machines for metals, non-wovens, geotextile, paper and composites. An overview of the services offered by Alliance include: new equipment, on-site engraving technicians, machinery installations, product development, machinery evaluations, used equipment refurbishing, new roll sets and technical support. From the sale of new machines to providing replacement rolls, parts or field service and support on your existing equipment, regardless of manufacturer, we are committed to being an expert resource for you.

American machine & rollform tech

In 1996 the Bradbury Group acquired American Machine & Rollform Tech. American has been manufacturing state-of-the-art roll forming, hydraulic punch, and cutoff machines since 1989. The company’s product line is manufactured and headquartered in Moundridge, KS. Businesses served by American include steel framing manufacturers, shelving and racking, and companies requiring small roll formed sections. Since its founding, American Machine has been dedicated to increasing customer profitability with efficient, reliable machines that offer high-quality output and a rapid return on investment. The advanced hydraulic punch, cutoff, and roll forming systems deliver performance you can count on.

athader s.l.

In 2012 Athader S.L, San Sebastian, Spain, joined the Bradbury Group. For over 20 years, Athader has delivered quality coil processing equipment to the European and Latin American markets. Their expertise in rotary and flying shears, multi-blanking and stacking, slitting, packaging and strapping, surface critical lines for stainless steel and aluminum as well as carbon steel, combined with the advanced leveling and coil processing technologies of The Bradbury Group, has allowed us to grow together as world leaders in the manufacture and supply of high quality, technologically advanced equipment for the industry.

beck automation llc

Beck Automation LLC., founded in 2001, is a leading controls provider for the metal forming industry. Beck Automation focuses on designing control systems for the roll forming industry, for both new and retrofit equipment to make production machines more efficient and profitable. Controls and related products are designed specifically for rollforming, cut-to-length, tube mills, portable rollformers, and folding machines. Beck's Connex™ enterprise business software integrates administrative, design, and production activities giving state of the art production control and reporting. Beck's greatest offering is the service and support in which they back those solutions.

bradbury group australia pty ltd.

Bradbury Group Australia, Pty Ltd, is a leading manufacturer of roll forming systems for light gauge framing components and rainwater goods, as well as solid core sandwich panel equipment.

bradbury group pu.ma.

Bradbury manufactures continuous and discontinuous sandwich panel lines using EPS, Mineral Wool, PIR/PUR, and flexible backing. To best serve the growing insulated metal panel industry, The Bradbury Group offers complete production lines including uncoilers, coil handling equipment, roll formers, double belt conveyors, and flying saws, punch and die tooling, control integration and rotary embossers.

bradbury metal tile roofing solutions

bradbury international uk ltd.

Bradbury International UK Ltd. facilitates sales, engineering, and service in Europe, Russia, U.A.E., Africa, and India for The Bradbury Group. Following the purchase of the Metform Engineering Ltd. (Metform UK) intellectual property along with many ex-Metform members of staff, Bradbury UK continues to support customers with existing equipment manufactured by Metform Engineering Ltd.

custom rollforming corporation

Originally Bradbury’s roll-formed products division, Custom Rollforming Corporation was given its own identity and incorporated in 1991. CRC now operates 12 production lines that turn out a wide range of roll formed metal products made to customer specifications from its own, separate facility in Moundridge, KS. CRC production ranges from simple to complex parts in many shapes and gauges.

hayes international

Hayes International, in Rotorua, New Zealand, joined The Bradbury Group in 1999. In business for 60 years, Hayes makes top-quality rollforming, slitting, folding, and related equipment for manufacturing roofing, wall profiles, structural sections, and other metal building products.

marion die & fixture

Marion Die & Fixture was acquired in January 1999. The division designs and manufactures equipment for the tool and die industry. Marion also manufactures precision tooling for Bradbury Group machines. Progressive dies, punch and notch dies, door emboss dies, and cutoff dies are supplied to a wide range of industries including appliance, automotive, garage door, HVAC, lighting, and metal building.

metform international

Metform International Limited, in Mississauga, Ontario, and The Bradbury Group formed a strategic partnership in 2005, giving both organizations the ability to share technology, cooperate in various markets in North, Central, and South America, and increase the reach of both organizations in these geographic regions. Metform supplies roll forming equipment for a variety of industries including automotive and heavy gauge roll forming.

press room equipment co.

Bradbury acquired Press Room Equipment Co. in 2023. PRE has over four decades of experience designing and manufacturing high-quality equipment for metal stamping and fabrication industries. PRE builds stock reels, pallet decoilers, straighteners, coil upenders, press feed systems, high-speed precision servo feeds, and automated processing lines in their Springfield, MO, facility. In addition to the PRE brand, the acquisition includes the Norwalk and Waddington Electronic brands.